Molding Process

1.Co2 Hand Molding.

2.PLC Automation with Continuous Sand Mixer –

10Tons/Hr.

3.Two Electrical Vibrator Table with capacity of

500kg for separate Cope and Drag molding.

Molding Box size of 30’’x30’’x6/5’’

(760mmx760mmx150/150mm).

VACUUM PROCESS MOULDING

1. Manufacturing of castings Through V-process with producing capacity upto 400Kg single piece with box size of (36''x49''x9'')*

2. Annual Production Capacity upto 1500MT in V-Process.

Molding Process

1.Co2 Hand Molding.

2.PLC Automation with Continuous Sand Mixer –

10Tons/Hr.

3.Two Electrical Vibrator Table with capacity of

500kg for separate Cope and Drag molding.

Molding Box size of 30’’x30’’x6/5’’

(760mmx760mmx150/150mm).

Core Shop

1.CO2 Core shooter.

2.Core oven with Continuous Bogie Heating.

3.Shell core dump box.

Melting And pouring Process

1.Electrotherm Make Induction furnace with Crucible capacity of 800Kg two pots & 450 Kw panel.

2. Pouring by filter type ladle.

Shot Blasting and Fettling

1.Batch Shot Blasting 2 Nos of 500Kg capacity, Make -Sree sakhti.

2. Swing frame grinder.

3.Teeth Profile Machine

Heat Treatment

1.Normalizing – Continuous heat treatment and Batch type Bogie Furnaces.

2. Quenching water media.

3.Fast Cooling Furnace.

4.Tempering Furnace

Machine Shop

1.VML 1000 :- Table size 1300x600mm

2. VTL :-Table chuck Φ600mm

3.Radial Drilling :- Table size 630x630x550.

Induction Hardening

Single Shot In-House Induction hardening set up.

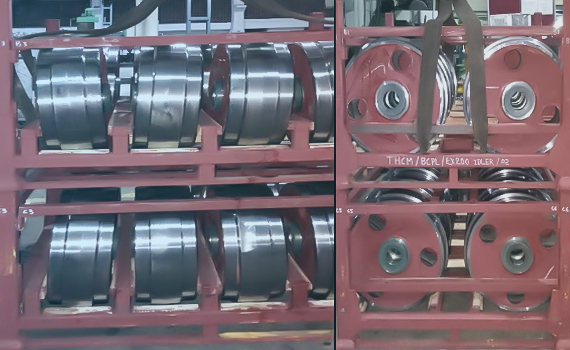

Packing & Dispatch System

Metallic collapsible boxes for casting packing.